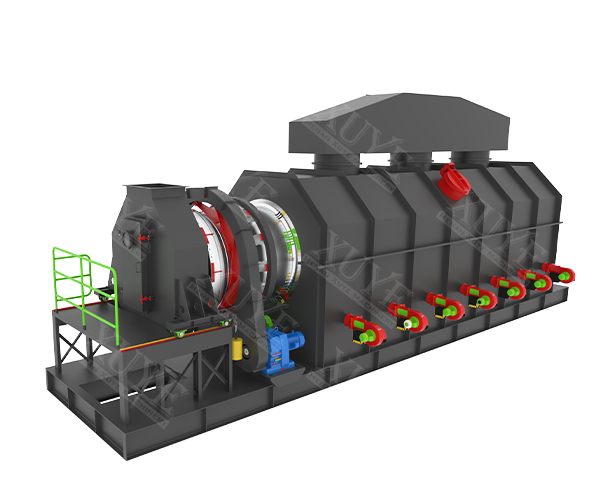

Activated carbon regeneration kiln

Activated carbon regeneration equipment restores the adsorption performance of activated carbon through heating reactivation method.- Raw materialWood, Coal, Coconut shells, Bamboo, Fruit pits

- ActivatorSteam

- Automation PLC

- capacityCustomizable

BRIEF INTRODUCTION

At present, various activated carbon-using enterprises produce a large amount of waste activated carbon every year. According to incomplete statistics, there are at least tens of millions of tons, but less than 20% is recycled, and most of it is disposed of as garbage incineration, which not only wastes resources, but also brings greater pollution to the environment. Human beings are facing the dual pressures of natural resource shortage and solid waste pollution, which threatens human survival and life. In view of the characteristics of activated carbon that is easy to regenerate after failure, our factory adopts a new process of thermal regeneration technology. Through regeneration, it can not only save activated carbon resources, but also reduce secondary pollution, with significant social and economic benefits and broad market prospects.

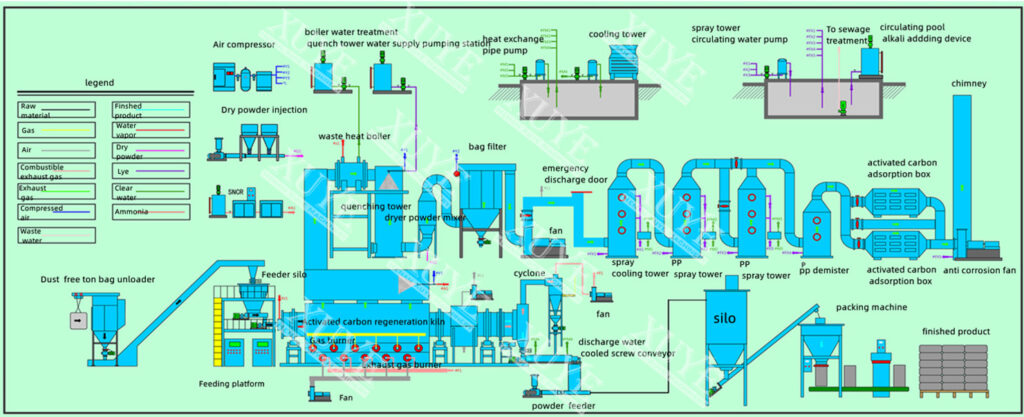

PROCESS

Activated carbon regeneration equipment is used to restore the adsorption performance of waste activated carbon that has adsorbed harmful substances. Through certain regeneration methods, the pore structure of activated carbon is restored, thereby extending the service life of activated carbon, reducing the frequency of replacement and reducing operating costs. The adsorption performance of activated carbon will decrease with the use time, mainly because the pollutants adsorbed on its surface will gradually become saturated or covered by other substances, so regular regeneration is required.

I. Drying stage: Heat the waste activated carbon with a moisture content of 20-60% to evaporate the adsorbed water in the carbon particles, and at the same time, some low-boiling organic matter will also volatilize.

2. Heating and carbonizing stage: The granular carbon is heated to about 850°C. As the temperature rises, different organic matter is eliminated from the activated carbon matrix in the form of volatilization, decomposition, carbonization, and oxidation.

3. Activation stage: After the organic matter is carbonized at high temperature, a considerable part of the carbide remains in the micropores of the activated carbon. At this time, an activator is required to perform a gasification reaction, so that the residual carbide is gasified into hydrogen, carbon monoxide and other gases at about 850-900°C, so that the surface of the activated carbon micropores is cleaned and its adsorption performance is restored.

The specific reaction formula is as follows:

C+H2O=CO+H2

2CO+O2=2CO2

2H2+O2=2H2O

C+CO2=2CO

Cooling and transportation of finished products: After the waste activated carbon is activated and regenerated in the continuous furnace, it enters the cooling equipment and adopts indirect cooling. The temperature after cooling is less than 40℃.

Finished product processing: Screening, grinding, homogenization, packaging, etc. of activated carbon.

Waste gas treatment: Harmful substances in waste gas can be removed through secondary combustion, SNCR, waste heat boiler, rapid cooling, dry deacidification, pulse dust removal, wet deacidification, demisting and other treatments.

Product Advantages

1.Wide range of use:

Can process powdered activated carbon, granular activated carbon, columnar activated carbon, honeycomb activated carbon, special-shaped activated carbon, etc.

2.High regeneration efficiency:

60-100%. Through the secondary activation method, not only the micropores of the waste activated carbon are reactivated, but also new micropores can be activated to restore and improve the adsorption performance of the activated carbon.

3.High economic benefits:

Higher thermal utilization rate, heat recovery rate, and less fuel consumption can be used to complete the regeneration of activated carbon.

4.High degree of automation:

The whole set of equipment adopts PLC automatic control, and sensors are installed at multiple process nodes of the whole production line for monitoring to ensure the safety of each link. The process parameters of the equipment can be automatically adjusted through PLC, which is highly flexible. The entire production line uses less labor.

5.Large output:

1-20t/d.

Click to expand all

Product Parameters

| Raw material | Coconut shell/nut shell/cylindrical activated carbon | Powdered activated carbon |

| Capacity | 5-20t/d | 3-10t/d |

| preprocessing | Screening and impurity removal | Screening and impurity removal |

| Regeneration kiln heating method | Internal heating/external heating | external heating |

| Regeneration carbon rate | 80-90% | 50-65% |

| Particle size requirements | 1-10mm | 0-1mm |

| fuel | natural gas/oil | |

| Regeneration effect (compared with original activated carbon) | 50-100% | |

| Regeneration temperature | 800-950ºC | |

| Finished product cooling method | Indirect water cooling | |

| Activator | Water vapor/flue gas | |

| Waste gas treatment process | Secondary combustion, SNCR, waste heat boiler, quenching, dry deacidification, pulse dust removal, wet deacidification, defogging, etc. | |

Click to expand all

CUSTOMER CASE

With advanced technology and reliable products, we provide efficient purification and green environmental protection solutions to many customers.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Xuye and I are working together to innovate. Activated carbon and biochar will help you improve your environmental protection business.

Henan Xuye Machinery Equipment Co., Ltd.

Henan Xuye Machinery Equipment Co., Ltd.