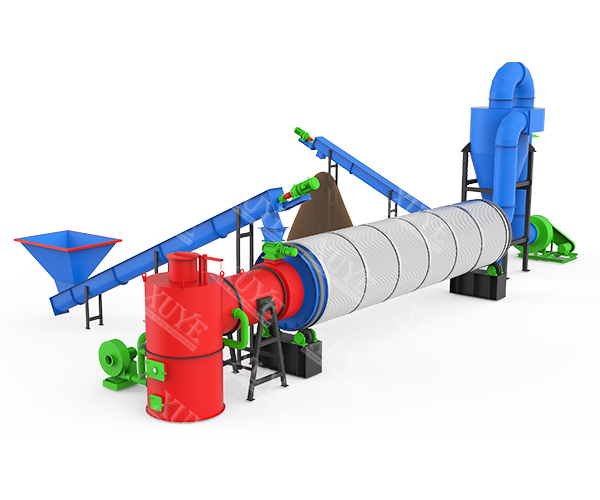

Rotary Dryer

Rotaty dryer is a drying equipment commonly used in industrial and agricultural production,- Production Capacity可定制

- Feed Particle SizeBelow 15mm

- Heat SourceNatural as, Coal, Diesel, Biomass

- Application AreasMinerals, fertilizers, grains, wood, chemical products and other materials

简介

Rotary dryer is traditional and reliable drying equipment, the material will be lifted up and fallen down by the lifting plates inside of the cylinder while the cylinder is rotating, the moisture in the material is continuously evaporated when the material contacts with the hot wind inside of the cylinder, to achieve the purpose of drying materials. It is suitable for drying sludge,biomass, coal, sand, animal dung, fly ash, clay, coal slime, ore, steel slag, quartz sand, kaolin clay, bentonite, sawdust, desulfurization gypsum, compound fertilizer,etc.

过程

The dewatered material will be transported to feeding head of the dryer through the screw conveyor after scattering, and then it will be sent into the inside of the dryer through the unpowered spiral sealing feeder (the patent technology of our company), and going through several following working areas after getting into the dryer: of the dryer is treated by dust removal and smoke washing to meet emission standards.

1. Material leading-in area

The material will come into contact with the high temperature negative pressure air after getting into this area and plenty of water will be rapidly evaporated, and the material can’t be formed into sticky stuff under the stirring of large guide angle lifting plate.

2. Cleaning area.

The material curtain will be formed while the sludge is lifted up at this area, and it will cause the material stick on the cylinder wall while it’s falling down, and the cleaning device is installed at this area (Lifting style stirring plate, X type second time stirring plate, impacting chain, impacting plate), the material can be quickly removed from the cylinder wall by the cleaning device, and the cleaning device can also crush the materials which are bonded together, so as to increase the heat exchange area, increase the time of heat exchange, avoid the generation of wind tunnel phenomenon, improve the drying rate;

3. Inclined lifting plate area

This area is the low temperature drying area, the slime of this area is at the low moisture and loose state, and there is no adhesion phenomenon at this area, the finished products reach the moisture requirements after the heat exchange, and then enter the final discharge area;

4. Discharging area

There aren’t stirring plates at this area of the dryer cylinder, and the material will be rolling to the discharging port.

The material gradually becomes loose after drying, and discharged from the discharging end, and then sent to the designated position by the conveying device, and the fine dust drawn out along with the tail gas is collected by the dust collector.

Hot air enters into the drying machine from the feeding end, and the temperature is gradually reduced at the same time of material convection heat transfer, and the water steam taken out under the suction of induced draft fan, and then emitted into the air after processing.

产品优势

1. The operation parameters can be changed according to the different material properties, the material in the dryer cylinder can form stable material curtain, to make the heat exchange more fully;

2. New feeding and discharging device, put an end to the phenomenon of the plug in feeding, incontinuity, nonuniform and material return of traditional dryer, and reduce the load of dust removal system;

3. The adjustable stainless steel plates’ sealing are adopted at the connection of the feeding and discharging devices, it’s with good sealing property, which greatly reduces the thermal losses inside of the cylinder, so as to directly reduce the fuel consumption;

4. Counterflow drying method, it can obtain higher evaporation intensity; downstream drying method and indirect drying method are suitable for drying materials which are sensitive to temperature;

5. Fuel can be diesel oil, heavy oil, and natural gas, gas, coal, electricity and biomass particles for environmental protection;

6. All kinds of different types of lifting plates combination, to ensure the hot air is in full contact with the material, and meet the needs of drying different material.

点击展开全部

产品参数

| 模型 | 气缸直径(mm) | Cylinder length(mm) | Cylinder volume(m3) | Cylinder rotary speed (r/min) | 电源(kW) | Weight(t) |

| 0.6×5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| 0.8×8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| 1×10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| 1.2×5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| 1.2×8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| 1.2×10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| 1.2×11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| 1.5×8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| 1.5×10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| 1.5×11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| 1.5×15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| 1.8×10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| 1.8×11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| 1.8×15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| 1.8×18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| 2×11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| 2×15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| 2×18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| 2×20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| 2.2×11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| 2.2×15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| 2.2×18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| 2.2×20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| 2.4×15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| 2.4×18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| 2.4×20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| 2.4×23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| 2.8×18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| 2.8×20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| 2.8×23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| 2.8×28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| 3×20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| 3×23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| 3×28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| 3.2×23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| 3.2×32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| 3.6×36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| 3.8×36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| 4×36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

点击展开全部

客户案例

凭借先进的技术和可靠的产品,我们为众多客户提供高效净化和绿色环保解决方案。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

旭业与我携手创新。活性炭和生物炭将帮助您改善环保业务。

河南旭业机械设备有限公司

河南旭业机械设备有限公司